As a leading polyester yarn manufacturer in China, we focus on producing high-quality 10S Polyester Spun Yarn Series. This series of yarns is made of high-quality polyester fibers and carefully manufactured through advanced ring spinning technology.

It has high strength, abrasion resistance and excellent dimensional stability, and can meet the needs of a variety of application scenarios. Our product specifications range from 10s to 10/12s, and are widely used in a variety of fields such as apparel fabrics, home textile products, and industrial fabrics. Whether it is knitting or weaving, it can show excellent performance.

In addition, we are well aware that the needs of each customer are unique, so we provide customized services, and can tailor yarn specifications, colors and performance according to the special requirements of customers to ensure that the products perfectly match the customer’s production process and end use.

With rich industry experience, advanced production equipment and strict quality control system, we are committed to providing high-quality, cost-effective polyester yarn solutions to global customers to meet the needs of different markets.

The 10S polyester yarn series, ranging from single-ply to 12-ply, offers various characteristics and applications suitable for multiple products.

The single-ply (10S) is lightweight and ideal for making thin fabrics like summer shirts and lingerie. As the ply count increases, the yarn becomes stronger and more durable, making it suitable for heavier applications. For example, 10S/2 double-ply yarn is used for medium-weight fabrics such as shirts and lightweight jackets.

Higher ply counts like 10S/4 and above are used for heavy-duty applications, including workwear, industrial fabrics, and outdoor gear like tents and backpacks.

The highest ply counts (10S/10 to 10S/12) offer ultra-high strength and are used for specialty products such as high-strength ropes, industrial filters, and heavy-duty upholstery.

Overall, the 10S Polyester Yarn series provides versatile options for both apparel and industrial textiles, with its strength and durability making it a preferred choice for a wide range of applications.

-

Yarn thickness

Yarn thicknessThe more strands, the thicker the yarn. For example, 10S single-strand yarn is relatively thin, while 10S double-strand (10S2) or more strands are thicker.

-

Strength

StrengthThe more strands, the stronger the yarn. For yarns of the same count, the more strands, the higher the strength.

-

Feel and appearance:

Feel and appearance:Single-strand yarn feels relatively rough, while multi-strand yarn feels finer and softer, and the fabric surface is smoother.

-

Application areas

Application areasSingle-strand yarn is often used for light fabrics or scenes with low strength requirements; multi-strand yarn is more suitable for making thick and durable fabrics, such as thick fabrics, industrial fabrics, etc.

-

Customer requirement submission

Customers can submit their requirements to us through various channels, including yarn specifications, colors, quantities and special requirements. We provide a variety of specifications from 10S to 10/12, and can tailor special specifications according to customer needs.

Customers can submit their requirements to us through various channels, including yarn specifications, colors, quantities and special requirements. We provide a variety of specifications from 10S to 10/12, and can tailor special specifications according to customer needs. -

Technical evaluation and quotation

Our professional team will conduct a detailed evaluation of customer needs, and provide accurate technical solutions and quotations based on factors such as the number of yarn strands, strength, and purpose. Our goal is to provide customers with the most cost-effective solutions.

Our professional team will conduct a detailed evaluation of customer needs, and provide accurate technical solutions and quotations based on factors such as the number of yarn strands, strength, and purpose. Our goal is to provide customers with the most cost-effective solutions. -

Production

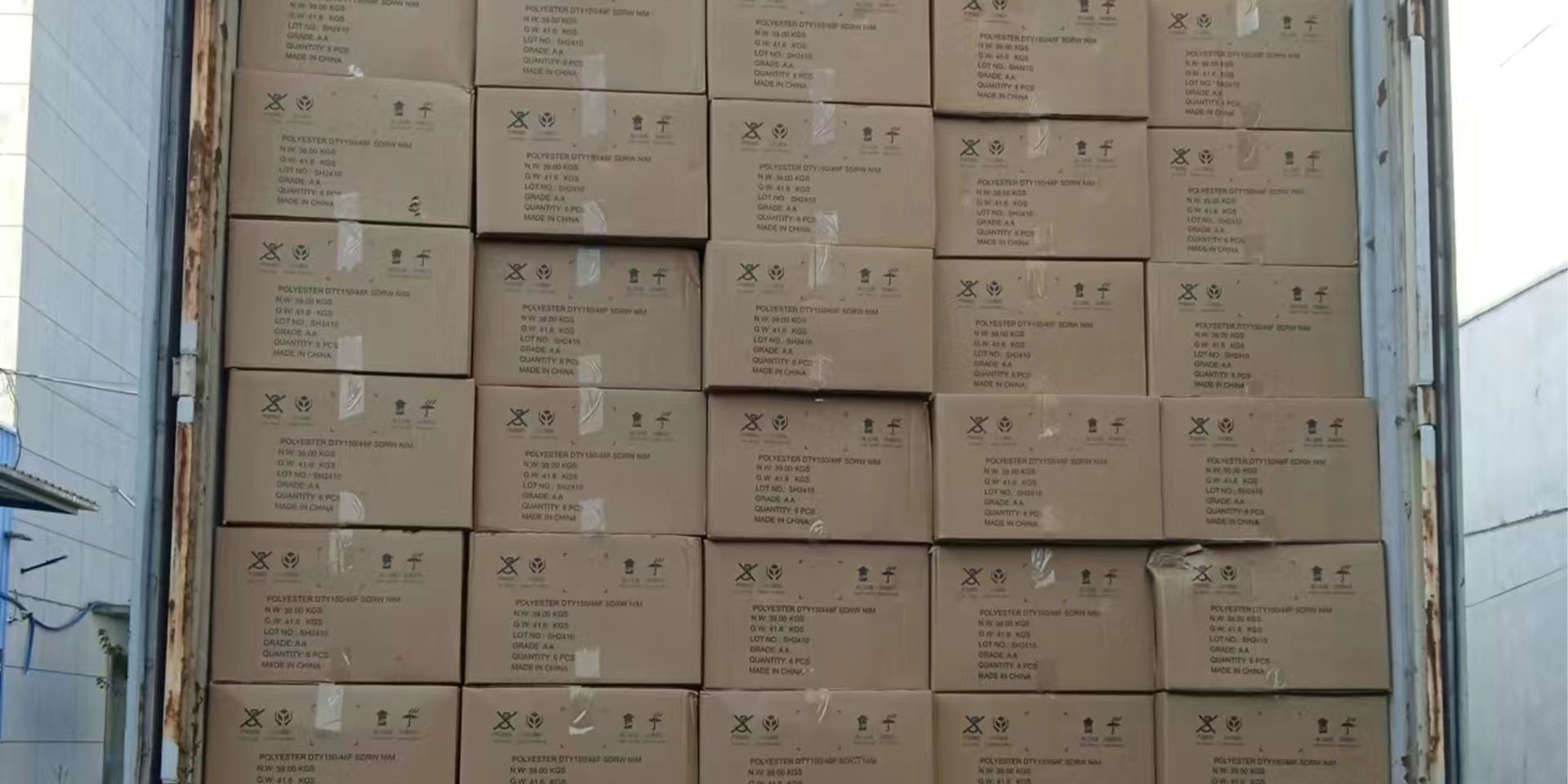

We have advanced production equipment and strict production processes to ensure stable and reliable yarn quality. During the production process, we will strictly control the quality to ensure that the products meet the high standards of customers. At the same time, we will reasonably arrange the production plan according to the customer's delivery time requirements to ensure the dual guarantee of production progress and quality.

We have advanced production equipment and strict production processes to ensure stable and reliable yarn quality. During the production process, we will strictly control the quality to ensure that the products meet the high standards of customers. At the same time, we will reasonably arrange the production plan according to the customer's delivery time requirements to ensure the dual guarantee of production progress and quality. -

Delivery and After-sales Service

We are committed to delivering products on time to ensure that customer needs are met in a timely manner. During the delivery process, we will select reliable logistics partners to ensure that the products are delivered to customers safely and on time. In addition, we provide a full range of after-sales services, including technical support, quality problem handling and customer return visits. If customers encounter any problems during use, our after-sales team will respond quickly and provide solutions to ensure that customers use it without worries.

We are committed to delivering products on time to ensure that customer needs are met in a timely manner. During the delivery process, we will select reliable logistics partners to ensure that the products are delivered to customers safely and on time. In addition, we provide a full range of after-sales services, including technical support, quality problem handling and customer return visits. If customers encounter any problems during use, our after-sales team will respond quickly and provide solutions to ensure that customers use it without worries.

-

How can I customize 10S polyester staple yarn?

Yes, all four of our companies have the same owner.

-

What is the minimum order quantity for 10S polyester staple yarn?

The minimum order quantity depends on your specific requirements; it is recommended that you contact our sales team for detailed information.

-

What is the delivery time for the products?

The delivery time depends on the order quantity and production schedule, typically 2-4 weeks after order confirmation.

-

How do you ensure product quality?

We have a strict quality control system, from raw material procurement to production process monitoring and finished product testing, ensuring the quality of each batch of products.

-

Do you provide samples?

Yes, we can provide samples for your testing and confirmation.