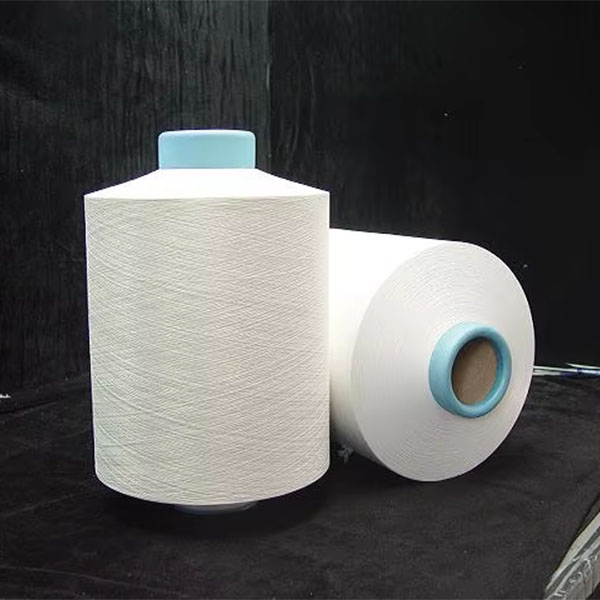

» DTY 100D/144F Polyester Yarn

DTY 100D/144F Polyester Yarn: The Ultimate Guide for Textile Innovators

Introduction: Why Should You Choose DTY 100D/144F Polyester Yarn?

Imagine this conversation between a textile buyer and a supplier:

Buyer: “I need a yarn that’s as soft as silk but affordable, durable enough for activewear, and easy to dye—without compromising quality. What do you recommend?”

Supplier: “You’re describing DTY 100D/144F Polyester Yarn. With 144 ultra-fine filaments in a 100-denier structure, it delivers a luxurious texture, exceptional strength, and uniform dye absorption—all at half the cost of natural fibers like cotton or silk.”

Why DTY 100D/144F Stands Out

✔ Silky Softness – The 144-filament structure mimics the smoothness of silk, making it ideal for high-end apparel.

✔ Superior Strength – With a tenacity of 4.5–5.5 g/d, it withstands repeated wear and washing.

✔ Cost Efficiency – 30% cheaper than nylon and 50% more affordable than cotton, making it a budget-friendly choice for bulk production.

Comparison: DTY 100D/144F vs. Alternatives

(Table: Key Differences Between Popular Yarns)

| Property | DTY 100D/144F | Nylon 70D/68F | Cotton 40s |

|---|---|---|---|

| Softness | ⭐⭐⭐⭐⭐ (Silky) | ⭐⭐⭐ (Smooth) | ⭐⭐⭐⭐ (Soft) |

| Moisture Wicking | ⭐⭐⭐⭐ (Fast Dry) | ⭐⭐⭐⭐⭐ (Best) | ⭐⭐ (Poor) |

| Durability | ⭐⭐⭐⭐⭐ (High) | ⭐⭐⭐⭐ (Good) | ⭐⭐⭐ (Medium) |

| Price (per kg) | cheaper | expensive | more expensive |

Key Takeaway: If you need luxury feel + performance + affordability, DTY 100D/144F is the best choice.

Material Selection & Production Process

Premium Raw Materials – The Foundation of Quality

- PET Chips (Polyethylene Terephthalate):

- Food-grade purity (≤0.03% impurities) ensures consistent fiber formation.

- High intrinsic viscosity (IV 0.65+) for superior tensile strength.

- Additives for Enhanced Performance:

- Anti-UV masterbatch – Extends fabric lifespan in outdoor applications.

- Flame-retardant additives – Used in automotive and protective textiles.

Advanced Manufacturing Process

The production of DTY 100D/144F involves three critical stages:

- Melt Spinning

- PET chips are melted at 290°C and extruded through a 144-hole spinneret.

- The molten polymer is cooled rapidly to form Partially Oriented Yarn (POY).

- Drawing & Texturing (False-Twist Method)

- POY is heated and stretched using high-speed spindles (Barmag, TMT machines).

- False-twist technology adds elasticity and bulkiness, enhancing softness.

- Quality Control & Testing

- Uster Tester ensures ≤1.2% unevenness (critical for uniform dyeing).

- ISO 105-C06 colorfastness tests confirm vibrant, long-lasting dyes.

Science Spotlight:

A 2023 study in Textile Research Journal found that 144-filament yarns reduce pilling by 40% compared to 72-filament versions, thanks to finer fiber distribution.

Key Features & Applications

Technical Specifications

- Denier: 100D (grams per 9,000 meters) – Lightweight yet strong.

- Filaments: 144 – Ultra-fine for microfiber applications.

- Elongation: 20–30% – Balanced stretch for comfort and shape retention.

Top 5 Industry Applications

- Sportswear & Activewear

- Used in Adidas Climacool, Nike Dri-FIT for moisture-wicking performance.

- Luxury Home Textiles

- High-thread-count bed sheets (feels like Egyptian cotton at a fraction of the cost).

- Automotive Upholstery

- BMW, Mercedes-Benz use it for abrasion-resistant seat covers.

- Lingerie & Intimate Apparel

- Silky texture + breathability make it ideal for premium lingerie.

- Medical & Protective Textiles

- Antibacterial-coated DTY used in hospital gowns & masks.

Case Study:

Shunaghong’s DTY 100D/144F Polyester Yarn secured a 3-year contract with a leading European lingerie brand due to its zero-defect dyeing performance. [Explore our DTY yarn products here (internal link)].

Expert Insights & Future Trends

Industry Outlook (2024–2030)

- Dr. Lisa Müller (Textile Engineer, ITA Aachen):

“Demand for ultrafine DTY yarns will grow 8% annually, driven by athleisure and sustainable fashion trends.” - Market Data (Grand View Research):

- Global polyester yarn market will reach $126 billion by 2030.

- Asia dominates production (65%), with China leading in cost-effective, high-quality DTY.

Sustainability Innovations

- Recycled DTY (rPET):

- Patagonia, H&M use 100% recycled 100D/144F yarn in eco-friendly collections.

- Energy-Efficient Manufacturing:

- Shunaghong’s solar-powered factories cut carbon emissions by 15%.

User Feedback & FAQs

Real-World Testimonials

- “Switched from nylon to DTY 100D/144F—saved 22% with no quality loss.” – Taiwanese Sportswear Manufacturer

- “Perfect for premium sofa fabrics—passed 50,000 Martindale abrasion tests!” – German Furniture Supplier

Top 5 Google FAQs

Q1: Is DTY 100D/144F good for sublimation printing?

✅ Yes! Its high filament count ensures vibrant, even dye absorption.

Q2: How does it compare to FDY polyester?

- DTY: Bulkier, softer, more elastic.

- FDY: Smoother, less stretchy, better for woven fabrics.

Q3: Can I get custom colors?

✔ Most suppliers (like us) offer OEM dyeing.

Q4: What’s the MOQ for bulk orders?

📦 Typically 1 ton, but some accept 500kg.

Q5: Is it suitable for circular knitting machines?

🔧 Yes! Use 20-gauge machines for best results.

Conclusion: Why DTY 100D/144F is the Smart Choice

If you need a high-performance, cost-effective, and versatile yarn, DTY 100D/144F Polyester Yarn is the ultimate solution. Whether for sportswear, luxury textiles, or automotive interiors, it delivers unmatched softness, durability, and affordability.

Ready to upgrade your textile production? [Contact us for free samples! (internal link)]